Case Study 1

Situation: An Australian mining company needs to perform live testing with a dozer to measure EQ bar deflection for the maintenance of the mining equipment (dozer). Current practice has no good solution for measuring the readout of the dial gauge.

Improvement

Through the use of a BlueDial wireless digital dial indicator we were able to remove the need for an operator to be in any dangerous situations with the live dozer in order to read the dial indicator. Also, the digital dial indicator gave an exact accurate readout, and with the use of the graphs created by the software, the read out process was sped up significantly.

Outcome

The Risk Score was reduced from major injury likely (ten times per year) to minor injury unlikely (one every ten years). Furthermore, the device helped to reduce the amount of exposure to risk by getting the job done quicker.

Case Study 2

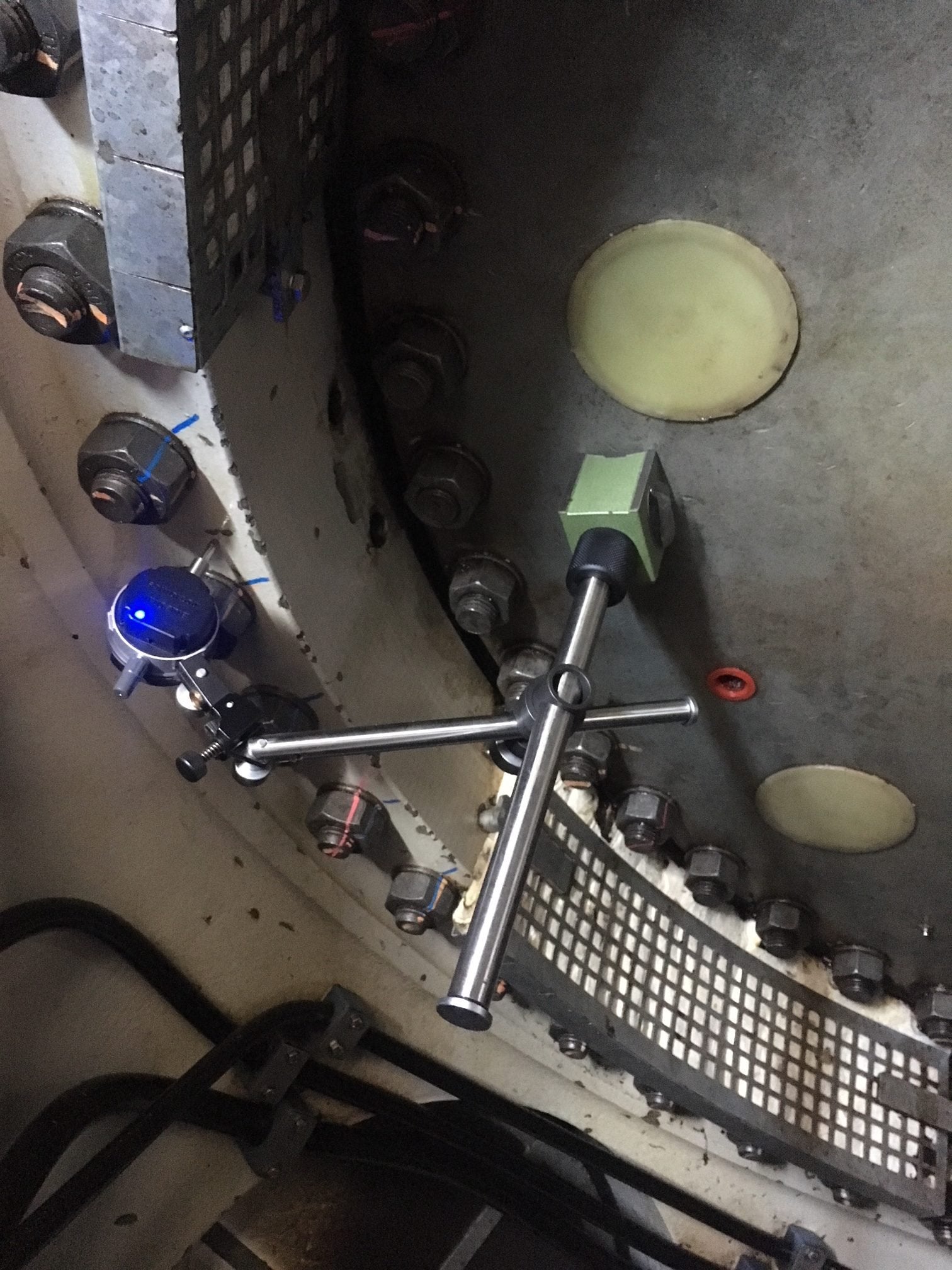

Situation: Blade bearing degradation in existing wind turbines is huge. Previously there was no testing performed.

Improvement

By measuring the blade pitching bearing run out, 30m blade length, maintenance operators are able to put a number to the bearing condition. Replacing bearings is a very expensive operation and having data to base decisions or prevent unnecessary replacement is a big improvement.

Outcome

Maintenance operators are able to measure and check whether bearings are still within tolerances. This gives a quantifiable measurement for maintenance decision making and prevents unnecessary expenses.

Case Study 3

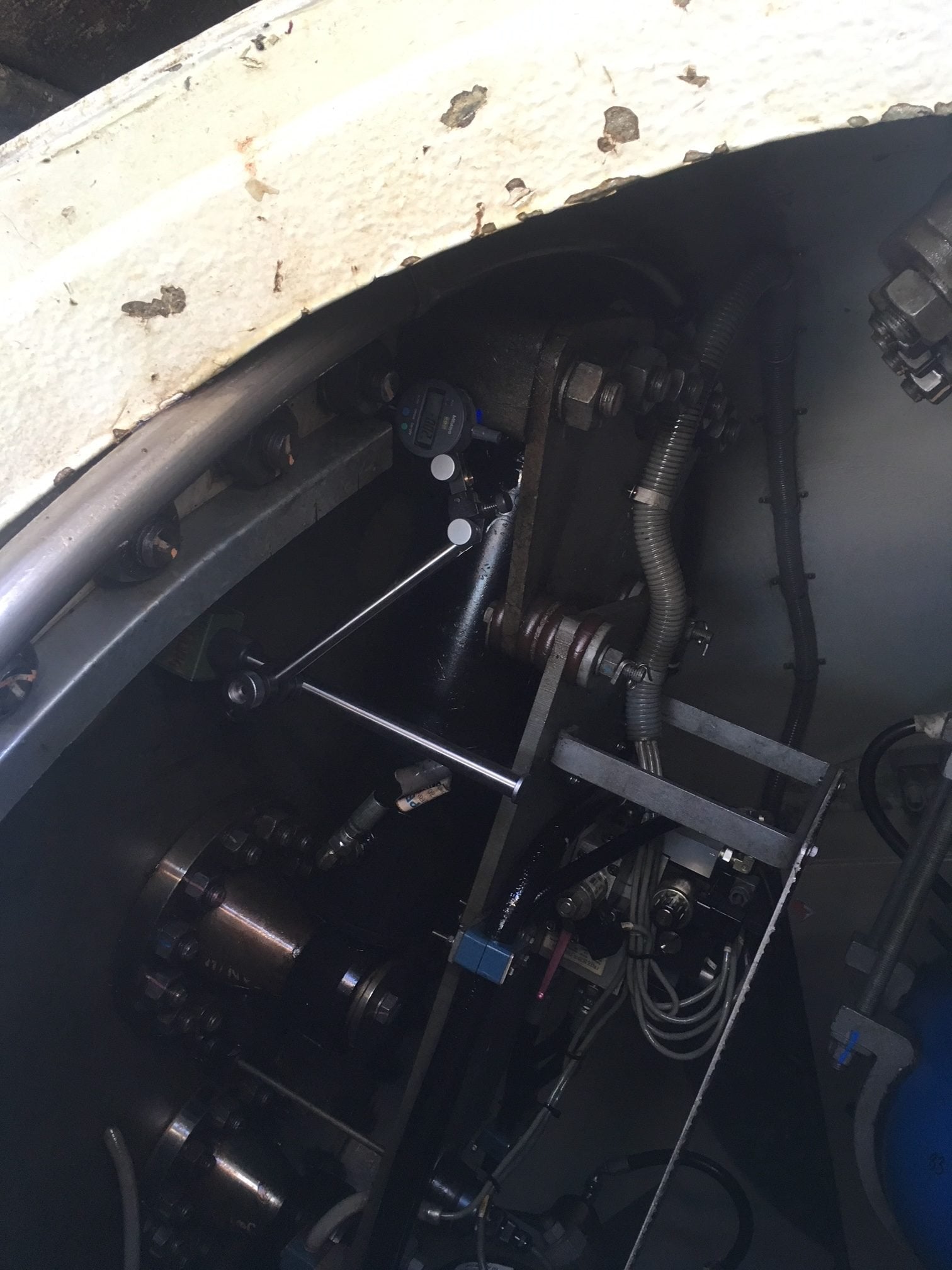

Situation: The orginal process was using a dial indicator and a mirror. This was “upgraded” to a wired digital indicator solution, which required wires to be run around the the traction motor. This obviously was a suboptimal solution for safety and work effeciency.

Improvment

Wireless measurement enabled by the Bluedial Bluetooth Digital dial indicator eliminated all unsafe practices and speed the job up considerably. Operators are now able to get the highly accurate digital measurement readouts straight into their hands without running sketchy wires everywhere.

Outcome

Saving hours from aligning the traction motor and eliminating dangerous practice.